SmartUQ 11.0 Now Available!

SmartUQ provides modern Artificial Intelligence, Machine Learning and Uncertainty Quantification tools that help our customers save time, decrease costs, improve quality, increase reliability, and reduce risk.

Our tools are optimized for engineering applications including simulation, digital twins, testing, and manufacturing. With industry-leading model accuracy and user-friendly GUIs and APIs, SmartUQ makes it possible to handle the toughest challenges and easily solve everyday problems.

“SmartUQ has the best prediction accuracy among all tools I have ever used.”

“SmartUQ's adaptive design can significantly reduce the number of required simulations [a 72% reduction] and lead to much higher model accuracy [96% reduction in reference prediction error]”

“Our Uncertainty Quantification discipline now uses SmartUQ as its central tool and with it we have helped save millions of dollars and thousands of hours of work.”

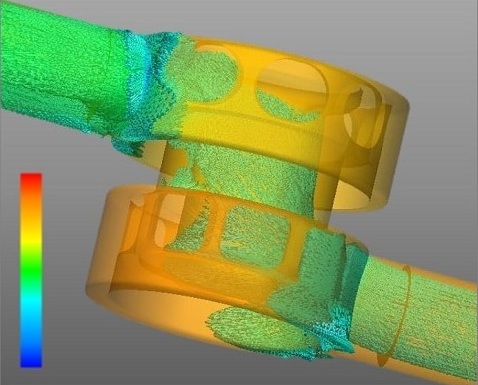

High-fidelity models take days or weeks to run, slowing design iteration and forcing compromises.

Traditional tools struggle to merge simulation and field data into actionable insights.

Complex systems and shorter release cycles leave little margin for error—recalls can cost $1B+ and damage brand trust.

Physical tests are expensive, destructive, and schedule-driven; teams often “test until they run out of budget.”

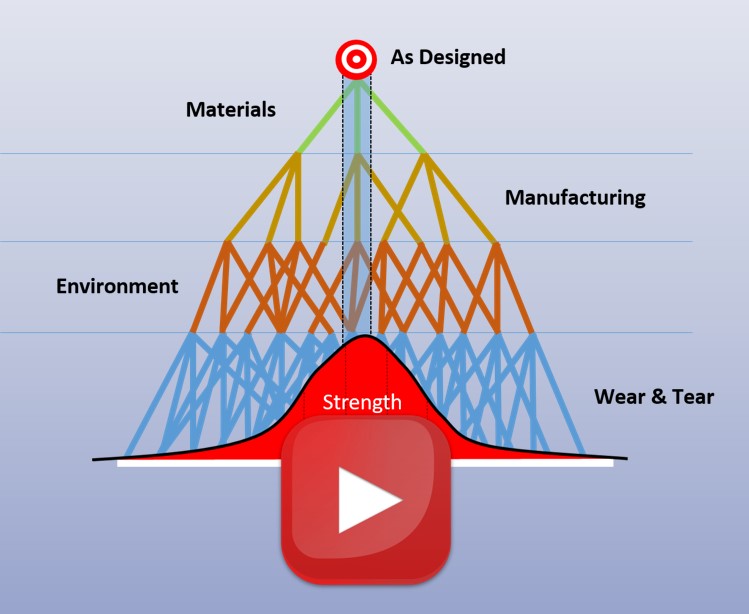

When uncertainty isn’t quantified, safety factors balloon—adding weight, cost, and time.

For applications like Digital Twins and certification by analysis, discrepancies between predicted and actual measurements must be reduced and quantified in order to trust predicted results.

Modern Engineering Teams Need SmartUQ to cut development time, curb cost, and protect product integrity—before small issues become million-dollar problems.

SmartUQ offers Industry-Scale Uncertainty Quantification

SmartUQ: Predictive Analytics for Engineering and Physical Sciences

Manage your risk with SmartUQ

Gain the competitive edge with your analytics